Researchers from industry, academia, and the U.S. Department of Energy (DOE) (Washington, DC) are working together on several new projects to research the corrosion of solar cells, with a goal of developing longer-lasting photovoltaic (PV) panels.

According to Sandia National Laboratories (Albuquerque, New Mexico), one of the leading partners on the program, corrosion can degrade many critical electronics and connections in these solar panels.

“It’s challenging to predict, and even more challenging to design ways to reduce it, because it’s highly dependent on material and environmental conditions,” says Eric Schindelholz, a Sandia materials reliability researcher who studies corrosion and how it affects PV system performance.

One particular challenge comes in reproducing the relevant environmental conditions to properly study how materials corrode in that setting.

“Along the coast of Florida, it’s humidity and sea salt in the air,” Schindelholz says. “In Albuquerque, we have high ultraviolet (UV) radiation, so UV might be one of the important parameters here. The parameters driving corrosion shift with location and materials. The challenge lies in identifying the important parameters—and then tuning the knobs in the lab to get something that replicates what we see in an outdoor environment.”

The electrical components in solar cells are initially protected from corrosion by encapsulating polymers, sealants, and glass. But water vapor and corrosive gases can eventually permeate those barriers as the materials and packaging degrade, according to Sandia’s researchers.

Collaboration across Departments

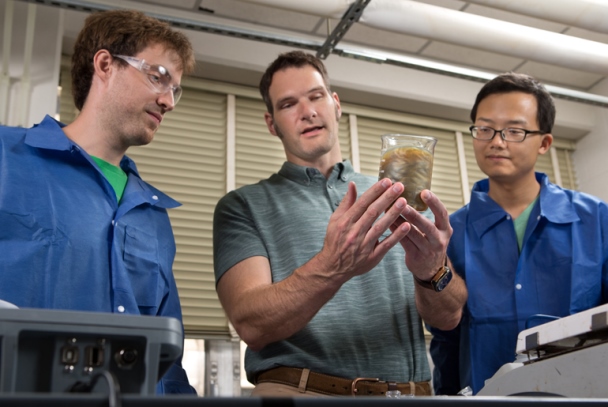

To address this, Sandia is asking researchers across its various departments to work together with a number of external groups on accelerated corrosion testing. For example, Sandia’s photovoltaic and distributed systems integration department is examining a previously unseen link between corrosion and the risk of arc faults in the electrical connections of PV systems.

Meanwhile, research from Sandia’s electronic, optical, and nanomaterials team is also targeting the development of new nanocomposite films as a possible barrier to corrosion.

“One of our primary goals is to predict how fast corrosion will occur and what damage it does, given certain environments and materials,” Schindelholz says. “This, in turn, gives us information to select the right materials for design or to develop materials for corrosion resistance for a particular environment. It also allows us to assess the health and operational risk of systems as they age. This is especially important for solar energy systems, which are susceptible to corrosion but are expected to last for decades.”

Accelerated Aging, Forensics Testing

Sandia’s Olga Lavrova is leading two projects focused on the reliability of PV systems, with emphasis on studying how aging affects solar cells and components and how they perform together.

One project, developed in collaboration with the Electric Power Research Institute (EPRI) (Palo Alto, California), is studying PV modules from different manufacturers to learn what types of degradation could be expected over 30 years. In turn, knowing specifics regarding the degradation could help identify ways to slow it down, she explains.

For this work, Sandia's researchers are applying accelerated aging principles to speed up their studies of slow-developing effects of degradation, including corrosion.

“Instead of waiting for 30 years of operation outside under the sun, we bring our PV panels inside to expose them to much higher concentrations of light or put them in thermal chambers to simulate the equivalent of years of temperature cycles,” Lavrova says.

Lavrova’s second project, studied in tandem with researchers at Case Western Reserve University (Cleveland, Ohio), is examining the study of corrosion effects from a forensic angle. In this project, researchers are looking back, rather than forward, to see what has already occurred.

To accomplish this, Lavrova and the researchers say they are using a “big data analysis approach” to study and analyze information from existing installations around the world.

“Is it 1% degradation a year, or is it 2%? Maybe we’ll see some that are a half percent, maybe we'll see some that are 10%,” she says. “Was it a bad original product, or was it installed in Costa Rica where the humidity is 80% every day?”

Funding Details

The work on those projects is funded by the DOE’s Durable Module Materials National Lab Consortium (DuraMat), created to speed up the development of new materials for PV modules while also increasing reliability and lowering the cost of solar power-generated electricity. As of now, raw materials account for about 40% of total PV module costs—but researchers are searching for ways to reduce that figure.

DuraMat, led by the U.S. National Renewable Energy Laboratory in partnership with Sandia, Lawrence Berkeley National Laboratory, and the SLAC National Accelerator Laboratory, is slated to receive ~$30 million in funding over the next five years from the DOE’s SunShot Initiative. The consortium is part of the U.S. Energy Materials Network (EMN), launched in 2016 by the DOE’s Office of Energy Efficiency and Renewable Energy (EERE) as a means to combine knowledge from the DOE’s national labs, academic leadership, and manufacturing expertise.

The goal of DuraMat is to build bridges between national U.S. laboratories and industry, so that research at the labs can be of benefit to the broader PV community, according to Sandia officials.

Using Nanocomposite Films as Barriers

Meanwhile, a separate project involving Sandia’s Erik Spoerke and a research team with the Polymer Nanocomposites Laboratory at Texas A&M University (College Station, Texas), is focused on the development of clay-based nanocomposite films to use as coating barriers against water vapor and corrosive gases. The team hopes these composite materials, some 100 times thinner than a human hair, can help withstand corrosion on solar cells.

Led by Jaime Grunlan, a Texas A&M professor, the researchers are investigating to see if the nanocomposite films can also prevent arc faults—discharges of electricity that can occur when electrical connections are corroded.

“It’s exciting to see how our long-term research in gas barrier and flame retardant coatings is being used to improve the efficiency and longevity of solar cells,” Grunlan says. “We are solving complicated problems using low-cost and environmentally benign materials, which is an added bonus.”

Spoerke compares the development of the nanocomposite films to the building of a home.

“It’s about assembling those structures in the right way so that you can use inexpensive materials and still get the benefits you want,” he explains. “If you build a house, it’s not just piling together the drywall and two-by-fours and shingles. You’ve got to use the two-by-fours to make the frame, set the drywall on the two-by-fours, and assemble the shingles on the roof.”

The overall goals of the projects are to find ways to use inexpensive materials, such as clay, to bring down the long-term costs of solar panels. The researchers believe these added efficiencies can help facilitate faster adoptions of solar technology in the future.

Source: Sandia National Laboratories, sandia.gov; Texas A&M University, engineering.tamu.edu.