The five largest coal-producing countries in the world are China, the United States, India, Indonesia, and Australia. These countries and their coal producers represent many hundreds of mines worldwide. In each of these mines, a variety of equipment is used to mine the coal by both underground and surface mining. The focus of this article is on underground coal mining; however, specific items (e.g., rock bolts) are common to many types of underground mining.

Although corrosion is a common problem in mines, as are material failures, there has been limited documentation of these issues in the literature or at conferences. The few presentations written are scattered throughout various journals, and are not always identified with mining or corrosion. Some of the frequently encountered problems are presented here to generate a more open discussion of corrosion and metallurgy in coal mining. Of course, much of what is described also applies to hard-rock mining.

Causes of Corrosion in Coal Mines

Probably the most important factor in corrosion of steels in coal mines is the mine water; however, just as with other industrial waters, the composition and corrosivity of these waters are highly variable. Yet little has been done by the mining industry to develop a comprehensive understanding of mine water corrosion, let alone allow effective modeling of corrosion caused by water. Rawat1 concluded that corrosion in coal mines was attributable to high relative humidity (>90%), high temperature (~30 °C [86 °F]), and airborne dusts. Moreover, the cause of acidity of mine waters is explained by the decomposition and oxidation of pyrites, the presence of peaty acids, and certain bacteria (Thiobacillus thiooxydans and Thiobacillus ferrooxydans). Furthermore, the chloride and sulfate content in mine water is a good indicator of corrosivity. It is also important to note that oxygen is always present in these waters.

In addition to mine waters, coal itself has been shown to be corrosive. This is not surprising since graphite is one of the most noble components of the galvanic series. Thus, galvanic corrosion should be expected. The bulk of study that is specific to the corrosivity of coal has been related to corrosion of steel equipment during the transportation of coal and coal slurries. Gardiner and Melchers2-3 have published several studies on corrosion from coal in bulk carriers, as have Waanders and Vorster.4 Zhang, et al.5 evaluated corrosion of coal mine equipment in coal slurries. These studies concluded that factors such as coal particle size, moisture content, and sulfur content have a significant influence on the corrosion of steel. In most cases, the corrosion takes the form of pitting attack.

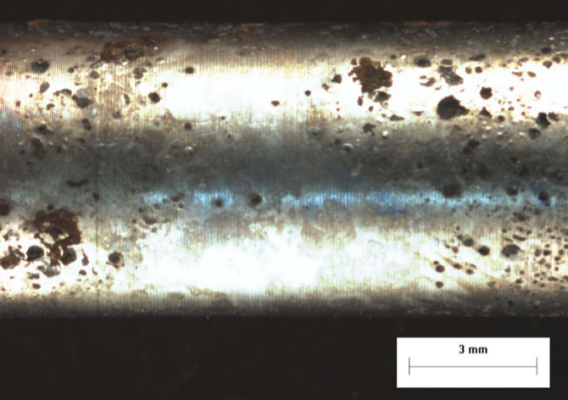

In addition to mine water and coal corrosivity, the presence of bacteria leading to microbiologically influenced corrosion can also be a factor. Common bacteria that cause corrosion in mines are sulfate-reducing bacteria and acid-producing bacteria. Figure 1 shows pitting on a Type 316 (UNS S31600) stainless steel (SS) valve stem in coal mine service.

Corrosion of wire rope is also a typical problem, as shown in Figure 2. Pitting of wire rope often leads to corrosion fatigue failure of the strands, but it also has been associated with stress corrosion cracking.6

Environmental cracking (EC) and corrosion fatigue are other common failure mechanisms in coal mines. Failure of rock bolts in mines, especially in coal mines, has attracted the greatest attention, primarily due to the sudden and catastrophic nature of EC. Figure 3 shows examples of typical EC field failures of rock bolts from coal mines. Gamboa and others7-9 have reported on rock bolt failures and performed laboratory studies. EC of rock bolts can largely be attributed to a hydrogen cracking mechanism that is identical to sulfide stress cracking in the presence of hydrogen sulfide (H2S) found in some coal mines. For this reason, the typical factors for this mechanism (i.e., acidic pH, moderate temperature, high stresses, and high-strength steel) are all important contributors to the risk of EC. Laboratory tests have been able to reproduce fracture features typical of hydrogen cracking in rock bolts and anchor bolts that have failed in service.7 Some of these features have been misinterpreted as ductile overload failure by others.10

The desire of mine operators to apply ever higher-strength rock bolts and anchors is of concern due to the greater potential for EC, especially from hydrogen-bearing environments.

Metallurgy Issues

In addition to corrosion and EC problems, there is an underappreciation of the risk of poor fracture toughness in standard rock bolt and anchor bolt steels. The most widely used standards for bolts and anchors are ASTM A61511 Grades 60 and 75, ASTM F43212 Grades 60 and 75, and, in some cases, ASTM A72213 Grade 150. These standards state minimum requirements for chemical composition, which results in the use of carbon-manganese steel bars for most manufacturing. Likewise, these standards specify minimum yield and tensile strengths with no maxima or hardness controls required, and do not include any requirements for minimum toughness. As is well documented, increasing strength often results in decreasing toughness, which leads to an easy, brittle fracture; however, even low-strength steels can exhibit poor toughness. Figure 4 shows the results of Charpy impact testing of A615 bolts from various manufacturers as a function of temperature. The lowest temperature of 10 °C (50 °F) is a typical underground coal mine temperature.

Figure 4 shows a large spread in fracture toughness of rock bolts that is due to a variety of factors associated with specific manufacturers, with some bolts being very brittle. This poor fracture toughness is not only an issue for highly loaded bolts, it also reduces resistance to EC propagation according to some.

Conclusions

The serious, ongoing problem of corrosion and cracking of alloys in coal mines and other underground mines, and the high variability of mine water corrosivity in the mining industry, largely have not been addressed by the corrosion community or corrosion science. The desire to use higher-strength steels, particularly for rock bolts and anchor bolts, presents a risk for a greater incidence of EC, which is dangerous in underground environments. There are many other corrosion issues associated with underground mining equipment that are not highlighted here but deserve greater attention.

References

1 N.S. Rawat, “Corrosivity of Underground Mine Atmospheres and Mine Waters: A Review and Preliminary Study,” Br. Corros. J. 11 (1976): pp. 86-91.

2 C. Gardiner, R. Melchers, “Corrosion of Mild Steel by Coal and Iron Ore,” Corros. Sci. 44 (2002): pp. 2,665-2,673.

3 C. Gardiner, R. Melchers, “Corrosion Analysis of Bulk Carriers, Part I: Operational Parameters Influencing Corrosion Rates,” Marine Structures 16 (2003): pp. 547-566.

4 F. Waanders, S. Vorster, “The Effect of Sulphide and Moisture Content on Steel Corrosion During Transport of Fine Wet Coal,” Hyperfine Interactions 1-3 (2013): pp. 29-34.

5 Q. Zhang, et al., “Effect of Coal Slurry on the Corrosion of Coal Mine Equipment,” Mining Science and Tech. 21 (2011): pp. 413-417.

6 S.Q. Wang, et al., “Stress Corrosion Behaviors of Steel Wires in Coal Mine under Different Corrosive Mediums,” Int. J. Electrochem. Sci. 7 (2012): pp. 7,376-7,389.

7 E. Gamboa, E. Villalba, A. Atrens, “Stress Corrosion Cracking of Rock Bolts,” Structural Integrity and Fracture: Proc. Int. Conf., SIF 2004, held September 26-29, 2004 (Australian Fracture Group, 2004).

8 E. Gamboa, A. Atrens, “Analysis of a Rock Bolt Failed in Service,” 15th International Corrosion Congress, paper no. 811 (ICC, 2002), pp. 1-9.

9 A. Crosky, B. Hebblewhite, “Failure of Rock Bolts in Underground Mines in Australia,” International Conference and Exhibition on Failure Analysis (IFCA), held November 20-22, 2002.

10 “Coal Mine Safety and Health Report of Investigation,” Mine Safety and Health Administration, CAI-2007-30, 2007.

11 ASTM A615/A615M-16, “Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement” (West Conshohocken, PA: ASTM, 2016).

12 ASTM F432-13, “Standard Specification for Roof and Rock Bolts and Accessories” (West Conshohocken, PA: ASTM, 2013).

13 ASTM A722/A722M-15, “Standard Specification for High-Strength Steel Bars for Prestressed Concrete” (West Conshohocken, PA: ASTM, 2015).