Built in 1943, the decommissioned Hanford nuclear production complex on the Columbia River in eastern Washington was once home to the world’s first full-scale plutonium reactor.1 The site's last reactor closed in 1987, and in 1989, the U.S. Department of Energy (DOE) (Washington, DC, USA) began large-scale cleanup efforts.

As part of those efforts, the DOE transferred radioactive and hazardous chemical waste from 149 single-shell tanks—built between 1942 and 1964—into 28 newer double-shell tanks for enhanced storage security until the waste can eventually be treated for disposal. However, the first double-shell tank to be built—Tank AY-102, constructed in 1971—was taken out of service in 2012 after a slow leak was discovered from its inner shell into the annular space between the inner shell and the secondary steel containment liner. The waste was contained in the annulus, and there is no indication that it leaked into the environment.2

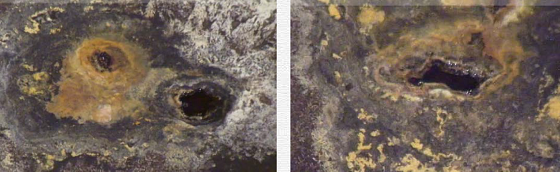

According to the DOE, the retrieval of the AY-102 tank cost more than $100 million and lasted more than a year. An inspection in 2017, after most of the waste had been removed from the tank, found widespread pitting at the base of the inner shell. Should other tanks at Hanford be taken out of service, costs could rise exponentially.

In 2018, a new investigative report delivered by the DOE’s Office of River Protection (Richland, Washington, USA) finds that other tanks at the facility also may have held waste with chemistry similar to waste stored in AY-102. However, the DOE cautions that it is too soon to tell whether similar leaking has or will occur. Testing is ongoing at Hanford, which holds a total of ~56 million gal (211,983 m3) of radioactive waste.

“The results of this study should not be interpreted as indicating that any of the storage tanks are currently leaking, or will leak, from the primary liner to the secondary liner, or from the tank to the environment,” says Jeremy Johnson of the DOE’s Office of River Protection. Johnson delivered his comments at a June 2018 meeting of the Hanford Advisory Board's tank waste committee.3

The site’s standard tank integrity program has included a video inspection of the tank wall and annulus floor areas approximately every three years, and an ultrasonic inspection every ~10 years, along with laboratory testing of the waste chemistry. Over the longer term, the liquid waste stored at Hanford will be vitrified. Vitrification is accomplished by mixing waste from the tanks with glass-forming materials in high-temperature smelters, which the DOE says makes the material easier to store safely. However, the planned vitrification plant at Hanford is not scheduled to begin operations until at least 2021. Furthermore, the process of removing all the liquid waste from the tanks and securely transporting it to the vitrification plant is expected to take many years. Thus, in the interim, maintaining the seals on the current tanks is essential.

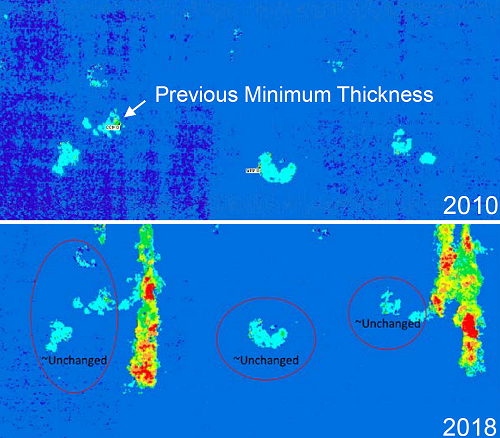

In the latest round of testing, investigators found that two tanks had spots showing significant thinning in a ring around the shell’s wall. According to the study, these tanks received condensate from ventilation systems, which could have formed a potentially corrosive layer. The report explains that the volume of condensate on the walls is made worse due to the waste in those tanks generating higher temperatures, which may have accelerated the corrosion. When compared to prior ultrasonic testing conducted in 2010, additional degradation was found in these tanks in 2018, with losses as high as 33% from the nominal wall thickness.

For the two tanks exposed to ventilation system condensate, the liquid will now be treated elsewhere at the site, according to the report. Later this year, new robots small enough to fit inside the ventilation spaces may also be used to learn more about the tanks’ current condition in the annulus.

While other tanks do not contain waste generating the same high temperatures, ultrasonic testing did find at least some thinning of the steel bottom in nine of the 11 inspected tanks. Though investigators did not pinpoint a precise cause for that thinning, the report notes that moisture can flow through and/or around the concrete foundation and near the tanks because there is no keyway or water stop between the shell and foundation. This exposes the secondary steel containment liner to moisture. The concrete foundation also contains drains to a sump system.

In the short term, the next steps include evaluating the effectiveness of corrosion inhibitors and examining methods to protect the outer shell exteriors from water intrusion and humidity, the report says. Core chemistry samples will be collected more frequently to analyze waste at the bottom of tanks judged to be most at risk.

To address these issues more specifically and receive feedback, the site has a tank integrity expert panel comprised of experts from a variety of private and U.S. government organizations, including national laboratories. The panel meets at least once a year; at these meetings, panelists provide independent advice and recommendations on existing and emerging tank integrity issues. The panel is also evaluating potential tank repair techniques for localized areas of corrosion. The most recent meeting was held June 27-28, 2018, and another is expected before the end of this year.

Source: Hanford Site, www.hanford.gov.

References

1 “Hanford Site,” Wikipedia, the free encyclopedia, https://en.wikipedia.org/wiki/Hanford_Site (July 18, 2018).

2 “Retrieval Activities Completed in Double-Shell Tank AY-102,” Office of River Protection Newsroom, March 8, 2017, https://www.hanford.gov/c.cfm/media/attachments.cfm/ORP/AY-102_retrieval_complete.pdf (July 18, 2018).

3 “Hanford Tank Integrity Presentation,” Hanford Advisory Board Tank Waste Committee, June 19, 2018, https://www.hanford.gov/files.cfm/Tank_Integrity_Presentation.pdf (July 18, 2018).