Since the release of the study, the IMPACT PLUS program, a robust suite of technical and business tools housed in a single online portal, has been used by a number of organizations to improve their CMS. A well-designed and implemented CMS is and should be a key part of an organization’s sustainable business practices. The NACE Technical Exchange Group (TEG) 531X was formed three years ago to discuss the concepts of material sustainability and material stewardship, including how these concepts related to corrosion management. A number of presentations regarding material sustainability and material stewardship have since been made at annual and regional conferences. More recently, the NACE Board of Directors has incorporated these concepts as part of its current three-year strategic plan for the association.

A CMS is a means of improving the implementation of corrosion control knowledge and tools within an organization. Furthermore, effective corrosion management has been shown to contribute to:

The IMPACT PLUS Corrosion Management Maturity Model, which is used to assess an organization’s CMS, provides:

• A platform for corrosion management professionals who desire to move their company to higher levels of performance

• A common language and structure needed to ensure communication throughout all levels of an organization

• An easy way for organizations to identify gaps in processes that could lead to the reduced lifecycle of assets

• A foundation to an organization’s goals for a more sustainable approach to corrosion management

The IMPACT PLUS program is administered by the NACE International Institute, which certifies “navigators” to work with organizations in implementing the program.

What is Material Sustainability?

Sustainability has a broad definition and can therefore mean different things to different people. In 1987, The United Nations “Brundtland Commission Report”3 defined sustainability as “Development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” The United Nations developed 17 Sustainable Development Goals (SDGs) in 2015 as a blueprint to achieve a better and more sustainable future for all. The role of the corrosion professional in contributing toward the UN SDGs was studied in an upcoming publication.4

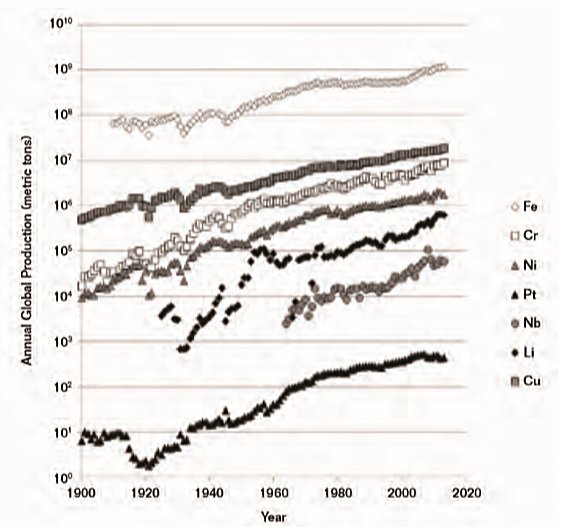

Material sustainability can be defined as the way materials are sourced, processed, manufactured into products, and maintained through the product lifecycle and redirected at their end of life. Current production and consumption models globally are unsustainable (Figure 1). Total demand for limited resource stocks could reach 400% of the Earth’s total capacity by 2050.

Meanwhile, the safe boundaries for four of the nine key ecological processes and systems that regulate the stability and resilience of the Earth ecosystem have already been exceeded. The corresponding economic impacts of these current trends are predicted to be severe, with global price volatilities and supply chain interruptions leading to as much as US$4.5 trillion in lost global economic growth by 2030, or US$25 trillion by 2050.

Predictions of materials’ supply constraints using reserve-to-demand ratios suggest that, within decades, we will be running up against planetary boundaries for several materials of industrial importance, such as nickel, copper, and precious metals. Material stewardship strategies in the 21st century should focus on decreasing this pace of consumption through the 4D strategies outlined in the next section.

What Is Material Stewardship?

Material stewardship is concerned with managing the flow of materials into society to improve its sustainability by mitigating environmental, economic, and societal impacts and maximizing its efficiency and durability.

In more detail, material stewardship investigates the maintenance and preservation of a material during its lifespan, including design, product ownership, and second life use (remanufacture, reuse, and recycle).

Four key strategies have been defined to pursue material stewardship in what is known as the 4 D’s approach:5

• Dematerialization

• Durability

• Design for multiple lifecycles

• Diversion of waste streams through industrial symbiosis

Material stewardship provides corporations, government organizations, and their stakeholders a model for preserving and extending the lifetime of materials, thus reducing the rate of materials throughput, cutting waste, and preventing the social, environmental, and economic costs due to materials failure.

The Linear Economy vs. The Circular Economy

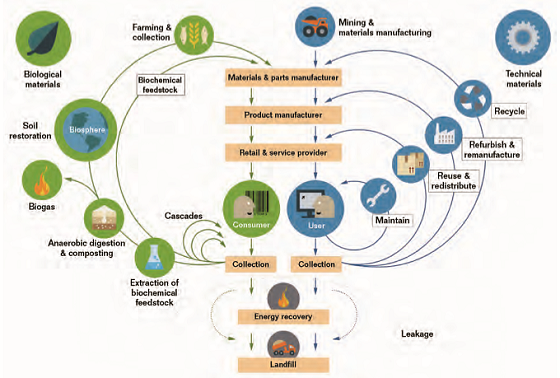

A new economic system and business strategy has been proposed that moves industry from the traditional model that follows a “take, make, use, and waste” process into a circular model where products and materials are kept within productive use for as long as possible, and when they reach the end of their use, they are effectively cycled back into the system.

By using the same principles that exist within nature, where biological materials are used over and over, we can design better systems for the use of technical materials (Figure 2). Moving to a circular economy will not only support a more sustainable future but will help businesses identify new opportunities with innovative products and services while optimizing their operations and supply chains.

Furthermore, there are significant energy savings to be realized when products can be reused rather than produced from raw material sources. Altogether, adoption of more circular thinking will lead to more profitable and long-term businesses. A number of areas requiring investigation for moving ahead with a circular thinking will lead to more profitable and long-term businesses.

A number of areas requiring investigation for moving ahead with a circular approach are identified in the recently published Circular Economy Handbook.7 The four areas are:

1. Operations: Addressing the value lost through operations and byproducts of business processes with respect to energy, emissions, water, and waste

2. Products and Services: Rethinking the design, lifecycle, and end of use of a product or service to optimize its usage, eliminate waste, and close product loops

3. Culture and Organization: Embedding circular principles into the fabric of an organization through redefined working practices, policies, and procedures

4. Ecosystem: Collaborating and partnering with public and private sector actors to create and enable an environment for collective transformation. This includes examining the essential role of investment and policy.

The Circular Economy Handbook builds on a previous publication (2015), Waste to Wealth,8 where a $4.5 trillion opportunity was identified by simply redefining the concept of “waste” as a valuable resource. The following four categories of waste were identified:

1. Wasted resources: Use of materials and energy that cannot be effectively regenerated over time, such as fossil energy and nonrecyclable material

2. Wasted capacity: Products and assets that are not fully utilized throughout their useful life

3. Wasted lifecycles: Products reaching end of use prematurely due to poor design or lack of second-use options

4. Wasted embedded value: Components, material, and energy not recovered from waste streams

Five business models (Circular Inputs, Sharing Platforms, Product as a Service, Product Use Extension, and Res

ource Recovery) were introduced by the authors in order to capture the value of redefining waste. A number of organizations have used these business models over the past five years in order to adopt a more circular approach. To help organizations transition from their current business to a more circular model, a number of learnings for particular industries have been included in the Circular Economy Handbook.

The objective of better product recovery in reducing waste can be illustrated by designing for end of use disassembly, refurbishment, and remanufacture. For example, the Scandinavian industrial group Moelven has designed walls for the interiors of buildings that can be taken apart and reassembled for a different design without requiring any new materials.9 As another example, Sony uses up to 99% of recycled plastics in its electronics. This not only leads to using plastics multiple times but has the added benefit of lowering the carbon dioxide (CO2) emission in Sony’s TV production by 80%.10 Materials can be chosen that are recyclable or compostable at the end of use. Ecovative Design uses mycelium, a mushroom material, as a bio-based packaging alternative to expanded plastic foams and other materials.11

Summary

The NACE IMPACT Study has already played a great role in showing the global importance of corrosion management across many industries. A well-designed and implemented CMS is and should be a key part of an organization’s sustainable business practices. Significant overlap between corrosion management, material sustainability, and material stewardship can be found. Associations like NACE International can help guide industries into a new era of more sustainable policies and practices. This is an opportunity to foster a technical society of forward-looking, proactive professionals equipped to support sustainability in tangible, meaningful ways through knowledge, standards, and a vision for future generations.

References

1 “International Measures of Prevention, Application, and Economics of Corrosion Technologies Study,” http://impact.NACE.org/economic-impact.aspx (Houston, TX: NACE International, 2016).

2 T.D. Kelly, G.R. Matos, “Historical Statistics for Mineral and Material Commodities in the United States,” supersedes Open File Report 01-006, https://minerals.usgs.gov/minerals/pubs/historical-statistics (Reston, VA: USGS, 2014).

3 “Brundtland Commission Report: Our Common Future,” World Commission on Environment and Development, 1987.

4 A.I. Williamson, M. Hernandez, C. Arroyave, “The Role of the Corrosion Engineer in Contributing towards the United Nations Sustainable Development Goals,” in press (Houston, TX: NACE, 2020).

5 C. Taylor, A.N. Sanchez-Sours, “Materials Stewardship: A Framework for Managing and Preserving Materials in the Circular Economy,” CORROSION 2018, paper no. 10832 (Houston, TX: NACE, 2018).

6 Ellen MacArthur Foundation, “Infographic: Circular Economy System Diagram,” https://www.ellenmacarthurfoundation.org/circular-economy/infographic.

7 P. Lacy, J. Long, W. Spindler, The Circular Economy Handbook—Realizing the Circular Advantage (Kings Cross, London: Palgrave Macmillan, 2020).

8 P. Lacy, J. Rutqvist, Waste to Wealth: The Circular Economy Advantage (Kings Cross, London: Palgrave Macmillan, 2015).

9 A Circular System, https://www.moelven.com/news/news-archive2/2018/a-circular-system (Moelv, Scandinavia: Moelven Modus).

10 “Leading the Development of Recycled Plastics,” Sony, https://www.sony.co.uk/electronics/sorplas-recycled-plastic.

11 Ecovative Design, “We Grow Materials,” https:/ ecovative-design.com (Green Island, NY: Ecovative).