In collaboration with industry stakeholders, the external corrosion prevention team at Enbridge (Calgary, Alberta, Canada) is developing a unification of its corrosion monitoring and mitigation strategies, with a goal of minimizing and effectively managing external corrosion risks.

“To demonstrate acceptable levels of external corrosion on a pipeline system, traditionally a technician is required to physically travel to test point locations across the network to make an electrical measurement for comparison with established criteria,” says Keith Parker, external corrosion specialist at Enbridge.

“The effort involved represents a significant risk for personnel who cover thousands of pipeline miles,” he adds. “With advancements in technology and expertise in the decades since the traditional method was formulated, our team believes there must be a more efficient way.”

That risk factor often includes established environmental risks associated with field surveys, as well as risks related to human logistics, such as driving and other modes of travel.

The IECM Approach

Known as the Engineered, Integrated Approach to External Corrosion Management (IECM), further background information and a case study based on this novel approach is available in the April, June, and August print issues of Materials Performance (MP) Magazine.

“The expected outcomes of such an approach are increased safety and reliability of the pipeline system, along with improvements in operating efficiency,” Parker explains. “The efforts are consistent with general industry trends to capitalize more on extensive historical data and increased use of analytical tools, including advanced diagnostics and modeling, to help manage the relevant corrosion threats.”

The objective is to capitalize on an organization’s internal expertise by integrating subject matter expert (SME) groups in external corrosion protection, pipeline integrity, and reliability.

The system calls for integrating all means and methods to assess, predict, and address external corrosion. This includes mechanistic modeling, remote monitoring, inline inspection, close-interval surveys, external corrosion direct assessment, traditional cathodic protection (CP) surveys, and engineering data analyses.

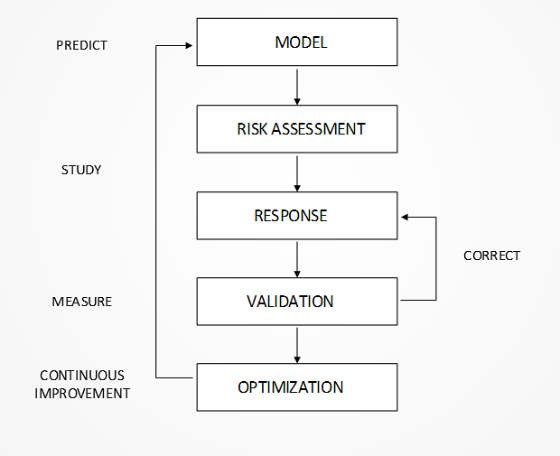

According to Parker, the program’s preliminary framework utilizes a development cycle with general phases including predict, measure, study/correct, and continuous improvement.

Expected Benefits

Going forward, expected general benefits of the IECM program include increases in reliability; improved operational and public safety; and increased efficiency in resource allocation associated with external corrosion protection. With respect to external systems and monitoring facilities, Enbridge envisions the following outcomes:

- Reductions in the number of test points that require monitoring through a rigorous engineering assessment of a pipeline’s CP conditions;

- Reduced field presence associated with ensuring compliance with AMPP (NACE) criteria;

- Reduced risk of stray current damage on Enbridge structures and foreign facilities;

- Reduced replacement and maintenance costs associated with maintaining CP systems.

Next IECM Steps

Over the remainder of 2022, the research team has planned several activities to further refine and develop many aspects of IECM. These include:

- Performing validation studies to confirm model predictions;

- Quantifying error(s) inherent in the model and incorporating into risk assessment;

- Confirming statistical methodologies for model alignment and data gap analyses;

- Utilizing case study results to determine response protocols and corrective actions;

- Incorporating mechanistic modeling into the selection of response protocols;

- Developing optimization processes.

“Once the technical foundation for the program has been fully developed and validated, the team plans to further integrate the various stages into an automated process to minimize assessment and response times,” Parker says.

“We believe the IECM approach, once fully developed and vetted, will allow our organization to push efficiencies in operations while maximizing environmental and public safety,” he adds. “The team will continue to develop and share IECM with the industry, and we encourage interested corrosion professionals to reach out to us with questions and offer input.”

For a further look about what this could mean for the corrosion industry, listen below to our recent MP podcast on IECM featuring Enbridge’s Parker; Trey Johnston, principal engineer at Corrpro; and Christophe Baete, manager of corrosion engineering at Elsyca. Tune in!

Sources: Enbridge, Corrpro, and Elsyca.