Located in Perlen, Switzerland, the Renergia Zentralschweiz AG waste incineration plant is a joint effort of waste disposal associations in the surrounding area. In addition to recycling waste from Central Switzerland, the plant supplies Perlen Papier AG with process steam, district heating networks with hot water, and provides electricity for approximately 44,000 households. After two years of construction, the Renergia plant went into operation in 2015.

But only months after starting up, plant officials witnessed corrosion on a fairly new boiler protected with weld overlay. A detailed inspection revealed accelerated degradation of the Alloy 625, just above the grate. The Alloy 625 weld overlay was shop-applied on the fireside water wall panels to protect boiler tubes from fireside corrosion.

Plant officials then evaluated four different thermal spray vendors who claimed to have a potential solution by having them each protect a patch inside the boiler. Eventually, a high-velocity thermal spray (HVTS) system from Integrated Global Services, Inc. (IGS) (Richmond, Virginia, USA) was selected.

Evaluation of Alternatives

The replacement of affected water-wall sections with new tubes would have been time consuming and expensive, IGS says, considering the estimated replacement frequency of five years or less. Thus, this was not a practical solution for the plant.

The replacement of affected water-wall sections with new tubes would have been time consuming and expensive, IGS says, considering the estimated replacement frequency of five years or less. Thus, this was not a practical solution for the plant.

Similarly, like-for-like weld overlay repair is intensive and time-consuming, and it requires preliminary grinding of the degraded surface layer prior to applying a new weld overlay. Moreover, the same corrosive media attacking the existing weld overlay would still be present.

As a result, the preferred option was thermal spray. This technology has had mixed results in boiler applications, IGS says, and the plant invited four thermal spray vendors to perform test applications on different sections within the boiler. Each vendor was given a side wall inside the two lines.

Out of four claddings applied, only two delivered satisfactory results, with the IGS solution determined to be best for performance and capacity. In this system, multiple HVTS guns can be operated inside the boiler at the same time with no capacity limitations.

Supported by comprehensive laboratory testing and field experience, IGS says its alloy cladding has no issues with permeability or disbondment and can offer lasting protection.

HVTS Application

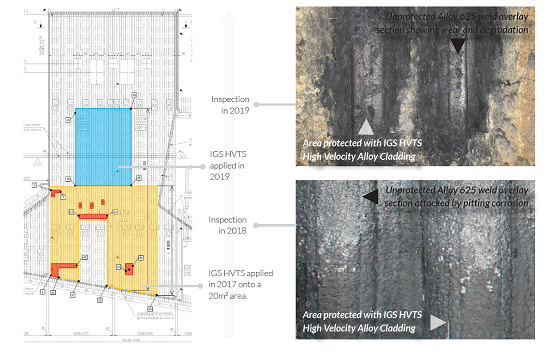

The HVTS application took place in 2017 on a 20-m2 area located on the left membrane wall. The plant also had a thermal spray (TS) coating applied by a different vendor on the right-hand side of the membrane.

These areas were then inspected in 2018 to determine whether HVTS and the other vendor’s TS were successful at stopping the weld metal overlay (WMO) degradation. The inspection of the HVTS/WMO interface showed that the area clad with the IGS solution was no longer affected by corrosion. However, the unprotected Alloy 625 WMO, as well as the other vendor’s TS system, continued to degrade.

From there, plant officials decided to extend the scope and apply the HVTS alloy cladding onto an additional ~20-m2 area in 2019. An inspection later that year confirmed that areas protected with the alloy cladding were not exhibiting any pitting corrosion or wastage, whereas adjacent unprotected Alloy 625 weld overlay sections were showing signs of wear and degradation.

Inspection and Results

Markus Benz, head of maintenance at Renergia, says a short inspection of the waste-to-energy boiler was performed in September 2018, which confirmed the desired performance of the coating. In January 2019, a deeper inspection confirmed the positive behavior of the cladding after 14 months in operation.

“The protected area has been doubled, so we expect to operate safely until our next turnaround in 18 months,” Benz says. Ruedi Kummer, director of the plant, adds that the idea to cover Alloy 625 with HVTS overlay “could have enormous potential.”

IGS says the proprietary HVTS coating systems can be used to solve corrosion and erosion problems in critical equipment assets, such as process vessels, towers, columns, and more. Additional information is available at the company’s website.

Source: IGS, www.integratedglobal.com.