Advanced corrosion and rust are playing significant roles in the failure of automobile brake pads, according to a two-part engineering field study by the Global Brake Safety Council (GBSC) (Toronto, Ontario, Canada) of more than 10,000 discarded brake pads.

The council was formed in 2014 to advocate and raise awareness for high standards in brake safety while ensuring responsible manufacturing in the automotive industry. The group of technical experts is comprised of professional engineers, design engineers, product development specialists, and research and development (R&D) professionals.

“As is increasingly the case, there is far more to visible or apparent corrosion than meets the eye,” GBSC writes in an engineering bulletin safety alert1 regarding the study’s findings. “In the case of brakes, red rust on a rotor surface that is visible through your wheel is just the tip of the iceberg. This visible layer of rust may even be easily wiped away by applying the brakes a few times while driving.”

“On the other hand, the effect of that same rust-producing environment on the brake pads—which you cannot see—is advanced corrosion that results in progressive deterioration and the rotting of the pads with rust, leading to separation between the brake pad and the brake system,” GBSC adds.

Data Collection

The latest portion of the field study examined more than 6,800 brake pads removed for replacement on vehicles from Toronto, Ontario, Canada; Cleveland, Ohio, USA; and Houston, Texas, USA.

These three markets were chosen based on the unique and dissimilar driving conditions in these cities. Toronto was classified as snow-bound, salted, and harsh; Cleveland as having severe winters with heavy lake-effect snowfalls and very pronounced seasonal differences; and Houston as humid and subtropical. Samples were collected over a 12-month span to provide a healthy sampling of the various seasons.

The brake pads were examined at the R&D lab of braking solutions company NUCAP Industries (Toronto, Ontario, Canada). Each as-received brake pad was cataloged, tagged with a number designation, documented by photography, and visually inspected.

These findings were compared to those from the first part of the study, which inspected more than 3,200 brake pads from just Toronto and Houston.

Findings and Failure Modes

In the latest study, over 50% of the samples did not show a reason for replacement. In these cases, more than half of the lining friction material remained, with no visible delamination or separation.

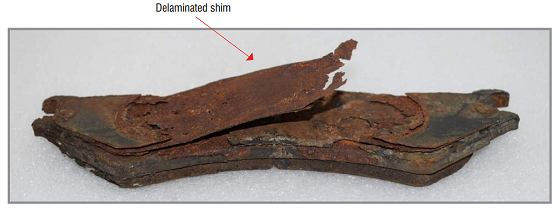

The samples were grouped into three categories according to the failure characteristics they exhibited. Nearly 12% were categorized as having excessive rust, with a disbonded shim and corroded pad abutment clips. Shims fit onto the back of brake pads and act as an insulating layer between the pad and brake caliper to dampen vibrations, and also as a thermal barrier to ensure consistent temperatures. The abutment clips hold the inner and outer pads in place and help to prevent rattles. The consequence of corrosion to these areas is increased noise and drag, which leads to early wear and higher fuel consumption.

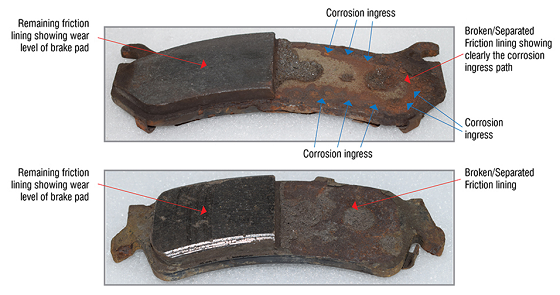

The proportion of samples showing excessive rust was consistent from the first part of the study to the second. However, a sharp increase was seen in a second category identified as edge lift, or “rust jacking.” This type of failure mode is due to a breakdown or delamination in the adhesive bond between the brake pads and the friction material, with symptoms that include noise, vibration, and roughness. The reduction in the lining friction material, which is seen as gaps at the backing steel rotor plate, can lead to a loss of braking power and vehicle braking instability.

In the second part of the study, which included Cleveland, edge lifting was noted in ~27% of cases—up from ~11% in the first part of the study that only included Toronto and Houston. “The tendency of Cleveland, lying just south of Lake Erie, to receive severe amounts of lake-effect snowfalls would be coupled with increased road-salt usage, leading to a faster corrosion rate of the brake pads,” GBSC writes, adding that other cities prone to rapid snow bursts are also likely subject to higher instances of failure modes.

About 6% of the pads showed a substantial part of the friction lining as broken entirely or significantly separated from the backing plate. This figure was consistent from the first to the second part of the study.

Conclusions and Outlook

In its conclusions, GBSC says the use of substandard products and materials—along with a lack of regulations and industry standard practices—are key drivers of the various failure modes.

More specifically, the council is concerned by the use of “black steel,” which it defines as hot-rolled steel that has not gone through the pickling and oiling process to remove impurities, rust, scale, and other contaminants prior to use. The presence of these contaminants in black steel, often used for the brake pad backing plate, can prevent coatings or anticorrosion treatments from adhering to the metal.

“This is seemingly taking on the specter of an epidemic, likely arising from pads produced with weak or questionable adhesive bonding and/or corrosion protection methodologies,” GBSC concludes. “This remains cause for major public safety concern, and ought to be a call for due consideration of industry and regulatory change.”

Source: Global Brake Safety Council, www.gbscouncil.com.

Reference

1 “Brake Pad Failure Modes and their Consequences – Part 2,” Global Brake Safety Council Engineering Bulletin, Bulletin No. 04.25.18., April 25, 2018, http://gbscouncil.com/wp-content/uploads/2018/04/BULLETIN-No.02.04.18.pdf (August 6, 2018).