Scientists with the Naval Surface Warfare Center, Port Hueneme Division (NSWC PHD) (Port Hueneme, California, USA) are working with a local company to use unmanned aerial vehicles (UAVs) and sensors to track corrosion or degradation on combat systems aboard U.S. Navy ships. Under the arrangement, NSWC PHD and remote-sensing technology company Aerial Alchemy (Thousand Oaks, California, USA) are partnering under a cooperative research and development agreement1 to examine how corrosion affects the performance of Navy ships’ combat systems.

Going forward, they want to find a way to detect corrosion, remotely. Aerial Alchemy develops medium and heavy-lift UAVs that use sensors equipped with lidar scanning and other imaging technology to accurately capture data used to generate a three-dimensional (3D) digital representation of a physical asset, also known as a digital twin.

Goals of the Partnership

The partnership’s goal is to explore using the company’s drones and its processing system and visual data to detect areas that may have corrosion. As a drone flies over a specified area of a ship, such as a hull or the rear, it transmits video to create a digital model of a ship. This contributes to a ship’s detailed analysis, including areas of concern for corrosion or rust.

Should the UAV and sensors detect corrosion, it will help give scientists early notice of the issue, according to Alan Jaeger, manager of the office of research and technology applications at NSWC PHD.

“The idea is whether we can use various sensors to identify that information without having to put human eyeballs on it,” Jaeger says. “If we can, then the next step is putting that on drones or unmanned aircraft, so we don't have to send a sailor on a ship; we can send a drone, and it can scan equipment and identify corrosion or undersurface damage, for example. If we can get that data, then we can start pre-planning for maintenance, preventative maintenance and repair operations.”

This is Aerial Alchemy’s second partnership agreement with NSWC PHD. The first initiative focused on proving the stability, reliability, and accuracy of the company’s UAVs in a maritime environment to successfully create an “as-built” digital model of USS Independence (LCS 2), which is used as a baseline digital twin. A digital twin is an intelligent digital representation of an analog asset or a 3D model, according to Chuck Spaulding, founder and CEO of Aerial Alchemy.

“We began working with the Navy in 2016 when everyone was trying to figure out what civil UAVs were, and what they meant to them,” Spaulding explains. “The Navy was interested in exploring the usefulness of drones for remote sensing and remote inspections of combat systems on surface ships, which led to the first [agreement] in 2018, and through that collaboration, we were able to create an exterior 3D as-built model of a ship at sea.”

Interpreting Sensor Data

With the second partnership, the team hopes to build on the successful results of the first and continue to improve precision navigation techniques. Their focus will be combining data from a thermal red, blue, and green sensor that a visible camera uses, as well as multispectral, hyperspectral, and tuning sensor wavelengths so they can be used to remotely detect and identify chemicals generated during the corrosion process.

“By themselves, the data from each of these sensors do not provide sufficient information for the specific identification and automatic evaluation of the corrosion state of an asset,” Spaulding says. “However, when combined with a stable platform with precision navigation such as lidar and synthetic vision to align the ‘blended’ sensor data and advanced computational approaches involving machine learning and artificial intelligence algorithms in a digital twin, this solution should provide a more objective rating of surface deterioration much more efficiently, cost-effectively and safer than a human inspector could.”

The teams anticipate that the drone-sensor technology bring many benefits to the Navy and the warfighter, including reducing the labor costs of inspections and the ability to inspect difficult and high-risk areas. That advanced and early detection, in particular, would give the Navy a leg-up in treating corrosion, said Zachary Stephens, a materials engineer with NSWC PHD.

“Because a lot of corrosion happens under the painted surface, you see it when it breaks through the painted surface, or you start to see physical flaws; and at that point, it's almost too late to do touch-up work,” Stephens says. “So the early detection will be very valuable for planning maintenance actions, and for knowing which system needs the maintenance and which ones don't, as well as moving onto our condition-based maintenance model rather than our preventative based maintenance model.”

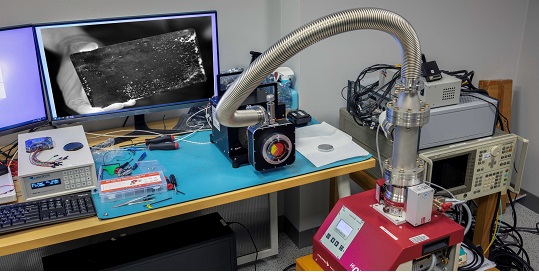

Armen Kvryan, lead materials engineer at NSWC PHD, has a doctorate in materials science and an extensive background on corrosion issues affecting combat systems from working in industry and academia. Kvryan, Jaeger, and Stephens along with advanced imaging technology company SAAZ Micro, Inc. (Simi Valley, California, USA) are currently conducting tests of the sensors in a laboratory to explore the different types of corrosion and degradation that the sensors can identify on different kinds of metals, such as aluminum and steel.

“Our initial research will be on what sensors to use to detect corrosion and then figure out what sensors we can use and what materials we can detect corrosion or degradation on, because composites are not metal, so they don't corrode,” Stephens says. “Although it would be ideal to have a [single] sensor that can detect all kinds of corrosion and degradation on the ship when you have composite versus aluminum or steel, they all have different signs and methods. One method may work on one type system but won’t work on another. The success of this test will determine where to focus our efforts.”

Next Steps in the Collaboration

Spaulding agrees that if the technology successfully identifies corrosion on combat systems, the system can assess issues on other parts of the ship and be used by other industries.

“To make a commercially viable product outside the Navy, we must also investigate the material properties of the hull superstructure and pretty much all exterior surfaces of the ship above the waterline that are subjected to a corrosive environment,” Spaulding says. “Navy warships are some of the most sophisticated machines globally, and the nature of combat systems with compound curvature and multiple angles, combined with composite materials, antennas, and sensors create complex geometries. If our technology can be demonstrated on combat systems, then it will have applicability on other parts of the ship that are less complex.”

Spaulding credits NSWC PHD for helping him navigate through the channels of working with the Navy. “The people we’re working with at NSWC PHD have been awesome and helped us through the process, and that’s significant if you’re a small company like we are,” he concludes. “They have removed many of the roadblocks that get in the way of good collaboration, making this a really enjoyable project.”

Kvryan says the agreement with Aerial Alchemy is another way to obtain information and experience from industry to pass onto the sailors and ultimately support the warfighter. “What I want is to not only solve a Navy problem, but to gain expertise and knowledge that I can bring back to the fleet so that we can then solve other problems using this newly acquired knowledge,” Kvryan says.

Aerial Alchemy and NSWC PHD are seeking additional partners or collaborators on the project. For more information, contact Jaeger at alan.w.jaeger@navy.mil or Spaulding at chuck@aerialalchemy.com.

Source: U.S. Defense Visual Information Distribution Service, www.dvidshub.net.

Reference

1 “Naval Surface Warfare Center, Port Hueneme Division Partners with Industry on Exploring Unmanned Aerial Vehicles and Sensors to Detect Corrosion on Navy Combat Systems,” Defense Visual Information Distribution Service News, July 14, 2021, https://www.dvidshub.net/news/400916/naval-surface-warfare-center-port-hueneme-division-partners-with-industry-exploring-unmanned-aerial-vehicles-and-sensors-detect-corrosion (Aug. 18, 2021).