First developed for use in the oil and gas industry, superalloy N07740 is now being used in solar power receiver tubes due to the desire to reduce CO2 (carbon dioxide) emissions. These particular tubes have a heat transfer agent (molten salt) that transfers and stocks solar energy.

The complex design of these systems is already challenging, and the added complication of molten salt corrosion makes it even trickier. Hence, the tubing utilized in these systems is typically made up of superalloys.

The Ni-Co-Cr superalloy is intended for use in high-pressure, high-temperature environments because of its stability, durability, and resistance to corrosion. It offers high-strength creep and fatigue features and can be utilized in temperatures up to 825 °C.

Molten Salt Corrosion

In their study, researchers Stephen McCoy, John deBarbadillo, Brian Baker, and Mark Anderson perform molten salt corrosion testing on the N07740 alloy—along with two others—N06625 and N06230. They also test the mass change, oxide thickness, and material strength of all three alloys.

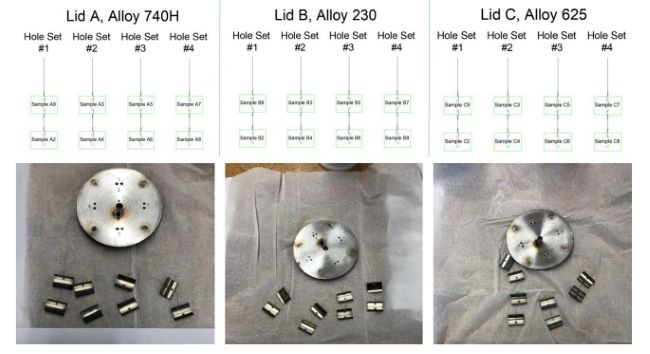

Corrosion behavior testing of N06625, N06230, and N07740 entailed exposure periods of 1,000; 2,000; 3,000; and 4,000 h at 600 °C. The thermal storage nitrate salt was made up of 60% NaNO3 (sodium nitrate) and 40% KNO3 (potassium nitrate). A total of 24 samples were tested: two samples of each alloy for each exposure time.

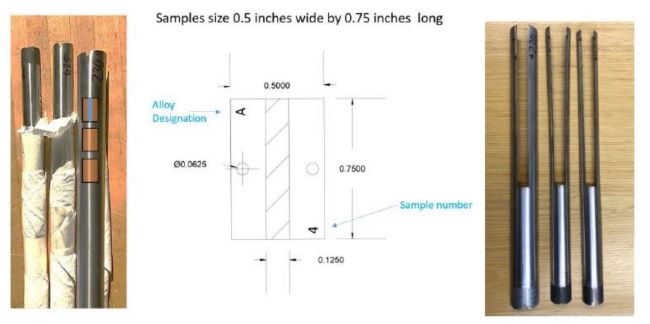

Samples were composed of electrical discharge machining (EDM) seam welded 1-in (2.54-cm) and 2-in (5.08-cm) tubes (Figure 1). After each exposure interval, weight analysis was performed.

The scientists’ objective was to establish whether the weight of the samples changed, and examine both the seam weld and base metal to determine the depth and scale of corrosion. They also gathered salt samples and measured the metal content within. And finally, one 1,000-h and one 4,000-h coupon (for each of the three alloys) underwent optical microscopy and scanning electron microscope (SEM) surface and cross sectional analysis.

Sampling Process

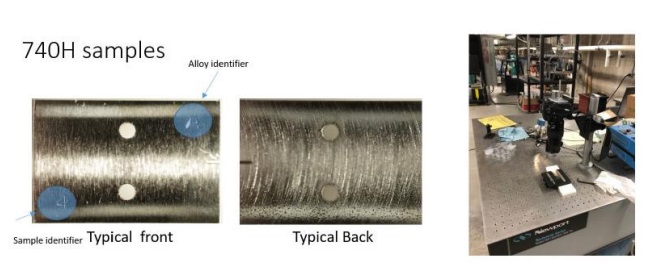

Prior to testing, the team stamped each sample with the alloy name to ensure correct identification upon removal from testing. Thickness and surface area of each sample was noted, and samples were cleaned, dried, and weighed.

They were photographed (front and back) and the two samples of the same alloy to be exposed for the same amount of time were connected with a nickel wire (Figure 2). Four sets (two samples each) of the different superalloys were suspended into the nitrate salt from a stainless steel lid (Figure 3).

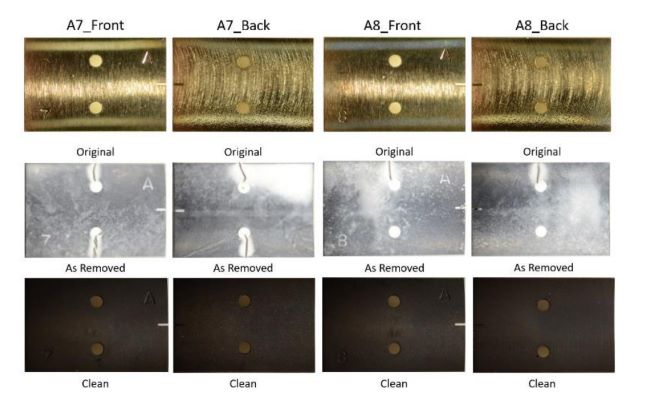

Samples were removed from exposure, cooled, photographed, and ultrasonically cleaned in distilled water. They were then dried, weighed, and photographed again. All samples experienced a minor amount of weight loss along with the development of a dulling oxide. Figure 4 (bottom) shows the photographs of the samples taken by the team.

Results from the study showed that alloy performance varied based on the information from the mass change and the oxide thickness tests.

Testing Results

Following the molten salt exposure, the N06625 sample experienced the least amount of mass loss change, followed by N06230, and finally N07740.

As far as oxide thickness values, SEM imaging revealed that N06625 was also found to be the lowest, followed by N07740 (which showed lower oxide thickness and a more compact oxide scale), and then N06230. Chemical analysis of the oxide layers found on the surfaces of the samples was mostly found to be nickel, along with some enrichment of iron.

Concentrated solar power (CSP) designs often include a multitude of constraints. Because of this, material strength must be taken into account. In this experiment, it was found that the ratio of ASME maximum allowable stress with alloy N07440 is 1.0, for N06625 grade 1 is 0.729, for N06625 grade 2 is 0.658, and for N06230 is 0.583 at 593 °C (1,100 °F).

The researchers discovered that, due to a recent assessment of the temperature dependence of tube material properties, elastic-plastic stresses/strains, and stress relaxation in a molten-salt external-cylindrical-tubular receiver, it can be determined that N07740 is advantageous over alloy N06230 with fewer panel substitutions for life extension. The panel life for alloy N06625 was found to be less than half that of N07740.

In conclusion, alloy N07740’s corrosion behavior, molten salt corrosion behavior, and its extremely high mechanical properties, ensure that it is a wise choice for use in supercritical CO2 systems that may be used for heat transfer in CSP systems. Utilizing alloy N07740 will help in reducing the lifecycle cost in comparison to the other alloys tested.

This article is based on CORROSION 2022 paper no. 17945, presented in San Antonio, Texas, USA.