Corrosion causes roughly 240,000 water main breaks in the United States every year. Outcomes of these failures include high-visibility repairs, hassles for the customer, and expense. Condition assessment is a fundamental preventative measure in detecting early corrosion in aging pipelines; however, it is not regulated in the water/wastewater industry. Condition assessment can be performed both directly and indirectly to indicate the resiliency and safety of pipelines.

Additionally, it is economically beneficial given that the estimated cost to replace all one million miles (1.6 million km) of currently corroded water and wastewater pipes in the United States is over $2 trillion. Following suitable design, operation, and corrosion prevention practices could have prevented between 35 to 50% of that cost.

Direct assessment methods offer important insight into the condition of pipelines through internally deployed tools or external excavations. This approach, however, has its disadvantages, such as safety concerns, shutdown time and expense, and cost of technology.

Approaches to indirect assessment, especially over-the-line potential surveys, which are usually applied to electrically continuous pipelines, reveal regions of active external corrosion in water and wastewater lines. Rubber gasket bell-and-spigot joints are used in most water and wastewater pipelines without electrical continuity.

Researchers Mersedeh Akhoondan, Daryl Akioka, and Graham Bell1 performed two case studies to determine if over-the-line potential surveys could be successfully applied to electrically discontinuous water/wastewater lines and if the results aligned with the direct assessment methods.

Indirect Assessment

Pipelines not using cathodic protection (CP) as well as CP-protected pipe with areas of depressed potentials can benefit from over-the-line surveys, which detect areas of corrosion. The researchers used three different survey types in the case studies—cell-to-cell potential survey, side drain potential survey, and cell-to-remote close interval potential survey.

To perform cell-to-cell potential and side drain surveys, a measurement of the earth’s potential gradient is taken by which reference cells are positioned at certain intervals along the pipe (e.g., every 5 ft [1.5 m]). In the cell-to-cell potential survey, the potential gradient is gauged by positioning an electrode on the pipe’s midline and another that trails at 5-ft intervals.

Then, the electrodes are moved concurrently along the alignment. The potential gradient measurement is in correlation with corrosion or the CP current running through the soil either to or from the pipeline.

For a side-drain survey, researchers place one reference above the pipe’s midpoint and another parallel to the pipe about 5 to 10 ft (- 3.05 m) away. The potential gradient is determined by moving both electrodes along the alignment concurrently. To determine cell-to-remote close interval potential, a stationary electrode is positioned at a remote location, while another is moved along the top center of the pipe.

All three types of over-the-line potential surveys help determine the location of corrosion in water/wastewater pipes. Furthermore, the investigators conducted corrosion soil surveys—including the electromagnetic conductivity survey, Wenner 4-pin survey, and soil sampling and laboratory analysis—in the case studies (Figure 1).

Direct Assessment

In the first case study, direct evaluation of the pipeline’s exterior was possible through the use of pot-holing and excavation. And in the second case study, magnetic flux leakage (MFL) technology was implemented as the direct internal condition assessment method.

Case Study 1

The first case study was performed on a 1,500-ft (457.2-m) segment of an electrically discontinuous concrete effluent sewer land outfall located in a transportation agency right-of-way. This area was considered environmentally sensitive and was located underneath a high-traffic bridge underpass. Plans to tear down and rebuild the nearby bridge were in place and the transportation agency was eager to learn the status of the pipeline and whether the nearby construction would have an impact.

Electrical continuity tests were executed because uncertainty existed regarding the functionality of the CP. Circulating current testing concluded that the electrical resistance values showed the pipe was not electrically continuous.

The researchers performed soil corrosivity tests to discover which areas of the pipe were prone to external corrosion using electromagnetic conductivity survey, Wenner 4-pin survey, and soil laboratory analysis. The electromagnetic conductivity survey and Wenner 4-pin survey revealed the soil was in the severely corrosive to corrosive range, while the soil laboratory analysis revealed that sulfate and chloride salts were predominant in the tested soil. The tests revealed a high probability for external corrosion on the section of pipe and the researchers recommend further testing to determine hot spots.

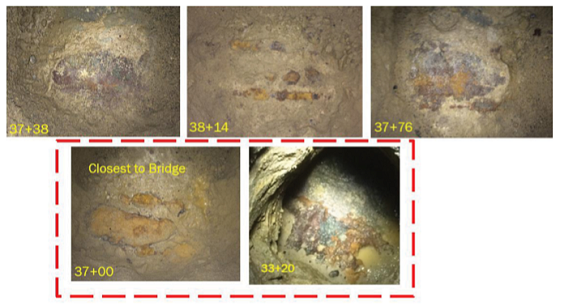

To identify the hot spots, cell-to-cell, side drain, and cell-to-remote cell potential surveys were completed (Figure 2), rather than traditional over-the-line surveys that would not be useful on an electrically discontinuous pipeline. The different tests allowed the investigators to analyze, understand, and identify the status of the corrosion and electrical continuity in the pipeline segment. They found the pipe to be electrically discontinuous in multiple areas and they expected the worst areas of corrosion to be under the bridge.

Direct assessment sites were chosen through the use of triage pothole images (Figure 3) and potential survey charts in an effort to expose joint locations. No sign of corrosion or deterioration was observed through visual inspection at the excavation sites. The pipe joints, however, were found to be in poor condition.

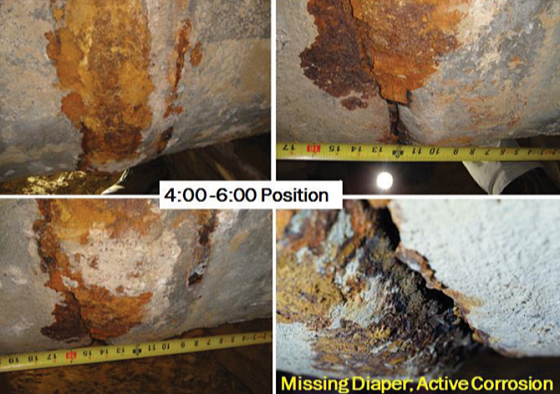

The first case study was successful in identifying areas susceptible to external corrosion through the use of over-the-line survey potentials. Direct assessment revealed that the pipe was in good condition, although, as suspected, severe corrosion was found in the joints (Figure 4), which may have been intensified by the addition of CP in an electrically discontinuous pipe.

Case Study 2

The second case study was performed on a 59.5-mile (95.75-km) pressurized cement mortar-lined and coated welded steel pipeline segment in the San Diego, California area. This pipeline is used as a water agency’s transmission line and is routinely inspected. It is not electronically continuous, nor is it cathodically protected.

An in-line inspection using MFL technology was completed to inspect the pipeline beginning at the point of delivery for roughly 10.5 miles (16.9 km). Prior to this inspection the pipe ovality was determined using a handheld laser distance reader used to detect radial distortion, which could hinder the MFL tool from being able to navigate the pipe.

Because MFL technologies have limitations and the potential for inaccurate data, over-the-line potential surveys were also performed. The researchers chose the side drain potential survey in this case study and locations of detected defects (metal loss) were determined.

Conclusion

Over-the-line potential surveys were conducted in two case studies that correlated well with direct assessment techniques when compared. Research determines that over-the-line potential surveys can successfully determine high-risk areas on electrically discontinuous pipelines.

Reference

1 M. Akhoondan, D. Akioka, G. Bell, “Over-the-line Potential Surveys for Indirect Condition Assessment of Water/Wastewater Pipelines: Case Studies,” CORROSION 2019, paper no. 13003 (Houston, TX: NACE International, 2019).