Researchers at Graz University of Technology (TU Graz) (Graz, Austria) have collaborated with the Austrian Society for Construction Technology (ÖBV) (Vienna, Austria) on the development of a new method to assess the condition of concrete structures.

In the LumAConM (high-resolution luminescent analyses of construction materials) project,1 the consortium is working on a simple and cost-effective method to enable a detailed assessment of the condition of concrete structures. The researchers say the method will also enable laboratory measurements with more precision.

This enables the structure’s service life, as well as any problem areas, to be assessed much more quickly and precisely than is possible with currently available methods of analysis, according to the research team. The researchers also hope that the new method will provide them with a better understanding of the course of essential corrosion processes.

“This knowledge enables targeted and cost-effective refurbishment and is essential for the development of new, sustainable, and durable materials," says Florian Mittermayr, researcher at the TU Graz Institute of Technology and Testing of Construction Materials.

Innovative Sensor Material

According to the researchers, the basis for the new process involves optical-chemical sensor technology. To this point, this advanced measurement analysis has been used primarily in biotechnology and medical technology. "We now want to use the tool to assess the condition of concrete infrastructure, and thus develop a completely new generation of sensors for the construction industry," says Bernhard Müller, chemist at the school’s Institute of Analytical Chemistry and Food Chemistry.

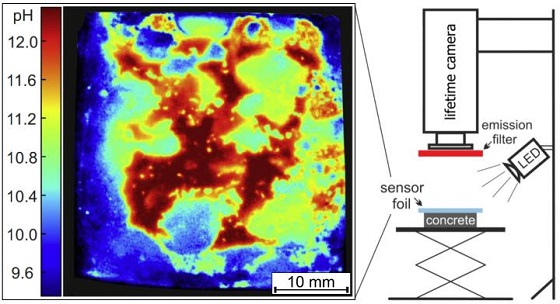

An example of this is an imaging measurement system implemented to quantitatively determine the pH value in cement-based materials. The research team explains that this parameter usually correlates directly with corrosion damage.

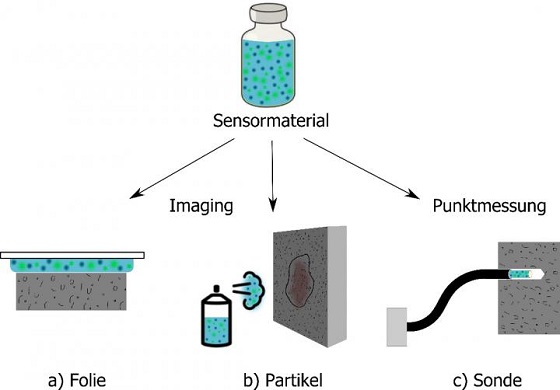

The measuring system consists of a plastic film with a swellable (i.e. water-absorbent) polymer layer containing an indicator dye and a reference dye, and the size of the sensor foil can be adapted to the size of the sample being examined.

The wet film is applied to the sample, and the pH distribution images are then generated with the aid of a special camera. According to the researchers, this technique has already been able to detect changes in the pH value in various building materials very accurately, as well as to characterize corrosion damage in great detail.

In the LumAConM project, the researchers say this measurement system is set to be further developed by the end of 2022 and will result in a versatile measurement technology.

Extensive Application Possibilities

On one hand, the researchers want to expand the measuring system to include other parameters, such as chloride. This would enable the combined determination of chloride concentration and pH directly on site at concrete structures, which the researchers say has not been previously done.

Chloride attacks, which can be caused by road salt in winter, pose a considerable risk of corrosion for concrete structures (especially for bridges) and are one of the most frequent causes of corrosion around the world.

On the other hand, the sensor material developed for the films can also be transferred to other sensor formats. On uneven concrete surfaces, for which the films are not suitable, the team would like to use sprayable sensor particles —and thus make the imaging technology available to expose underlying structures. At present, that condition is assessed via core sampling and complex chloride determination by chloride titration, according to the research team.

Longer-Term Goals

The researchers also plan to make miniaturized probes based on optical fibers. This would not only enable measurements to be taken on the concrete surface, but would also allow depth profiles to be easily created using drill holes.

“I think that in the medium to long term, the procedure can replace other, more expensive, and more complex investigation methods to a large extent, and make quality management in concrete construction much easier,” says Cyrill Grengg of the TU Graz Institute of Applied Geosciences.

The engineering sector project LumAConM, which was submitted by ÖBV, is funded in the framework of the collective research program supported by the government’s Austrian Research Promotion Agency (FFG) (Vienna, Austria). The FFG is the national funding agency for industrial research and development in Austria.

Source: TU Graz, www.tugraz.at.

Reference

1 “TU Graz Researchers Want to Fundamentally Improve Concrete Diagnostics,” EurekAlert! Latest News Releases, June 26, 2020, https://www.eurekalert.org/pub_releases/2020-06/guot-tgr062620.php (August 18, 2020).