The Transportation Safety Board of Canada (TSB) recently released its investigation report (P22H0023) into a pipeline rupture that resulted in an explosion and fire near Fox Creek, Alberta.

On the morning of April 7, 2022, an 8-inch (219.1 mm) natural gas pipeline operated by NOVA Gas Transmission Ltd. ruptured. The escaping gas ignited and resulted in a four-hour fire, which burned a 12,000-m2 area. The fire self-extinguished after the flow of gas was stopped by manually closing isolating valves upstream and downstream of the rupture.

In all, approximately 3,750,000 m3 of natural gas was released in that incident. There were no injuries, and no evacuation was required.

After the occurrence, NOVA Gas Transmission Ltd. replaced the damaged sections of pipe and initiated steps to permanently shut down the entire pipeline.

Investigative Findings

An examination of the ejected pipe pieces found significant corrosion along one edge, which identified the probable rupture origin. The edges of the ejected pieces showed features consistent with ductile fracture. No indication of prior cracking, brittle fracture, or any flaw such as stress corrosion cracking was observed. The minimum thickness measured at the probable rupture origin was 0.49 mm, an 88% reduction of the original wall thickness.

The recovered pipe sections were examined to determine the condition of the coating and the extent of external corrosion. The external coating was originally installed in the field by applying an adhesive to the pipe and then wrapping polyethylene tape in a spiral configuration.

As part of the laboratory examination, three stages of 3-dimensional laser scans were performed. The initial scan was performed with the tape coating still in place, followed by a scan with disbonded tape removed. A final scan was conducted after the pipe was sandblasted to remove all remaining tape coating, which revealed the corroded pipe surface.

The areas of pipe exposed to the fire did not have any pipe coating remaining. The general condition of the remaining polyethylene tape coating was found to be very poor. As such, TSB concluded that the pipeline ruptured due to reduced pipe wall strength from external corrosion.

Over time, the external coating system had degraded, exposing the pipe’s surface to the external soil environment. Analysis of soil samples and corrosion products found bacteria such as pseudomonas and acinetobacter, both of which are known to degrade hydrocarbons. These bacteria can gradually degrade the adhesive used to fix the field-applied tape coating to the pipe.

Generally, potential integrity threats due to bacterial activity are supposed to be accounted for as part of a pipeline operator’s integrity management program.

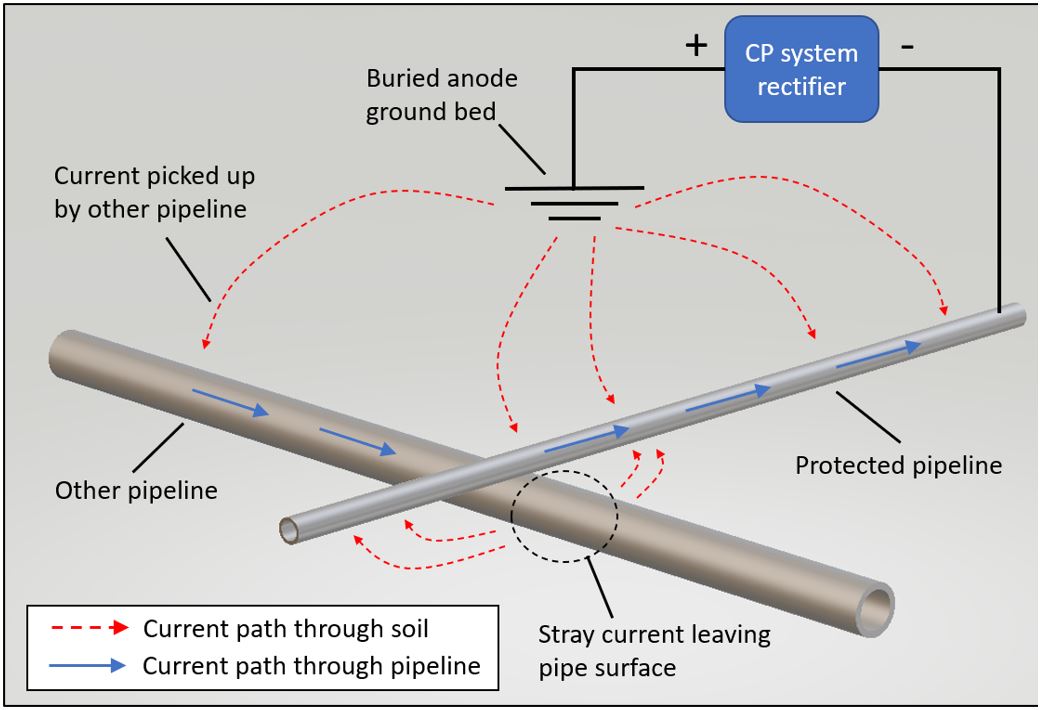

Here, an impressed current cathodic protection (CP) system had been installed to protect the pipe surface from corrosion in the event of degradation or failure of the external coating. But in this occurrence, the CP system was not adequately protecting the exposed pipe surface, as intended.

The pipeline’s proximity to a nearby third-party pipeline—combined with a degraded pipe coating, low soil resistivity, and an incomplete electrical CP bond—contributed to stray current interference, according to the TSB. This prompted accelerated external corrosion.

On Feb. 14, 2016, the pipeline had been internally inspected, and no corrosion was detected at the occurrence location. The re-inspection interval was established at seven years, with the next scheduled inspection to take place before February 2023.

But that previous in-line inspection did not take into account the threat of localized accelerated corrosion due to CP issues, according to the TSB. As a result, the corrosion at the rupture location grew to the point of failure before its next scheduled inspection.

The complete investigation report is available here.

No Centralized System

Currently, there is no centralized system in Canada for consolidating information about pipeline CP system locations and operating characteristics. In this case, the pipeline’s proximity to a nearby pipeline—combined with a degraded pipe coating, low soil resistivity, and an incomplete electrical bond—contributed to stray current interference.

If pipeline operators are not fully aware of the operating characteristics of third-party CP infrastructure located in close proximity to their pipelines, CP effectiveness may be compromised, according to the TSB. In turn, this increases the risk of corrosion.

About TSB

The TSB is an independent agency that investigates air, marine, pipeline, and rail transportation occurrences. Its sole aim is the advancement of transportation safety. It is not the function of the board to assign fault or determine civil or criminal liability.

Source: TSB of Canada, www.tsb.gc.ca/eng.